Pregelatinized Starch

There is a big market for pregelatinized or precooked starches in food and non-food industry.

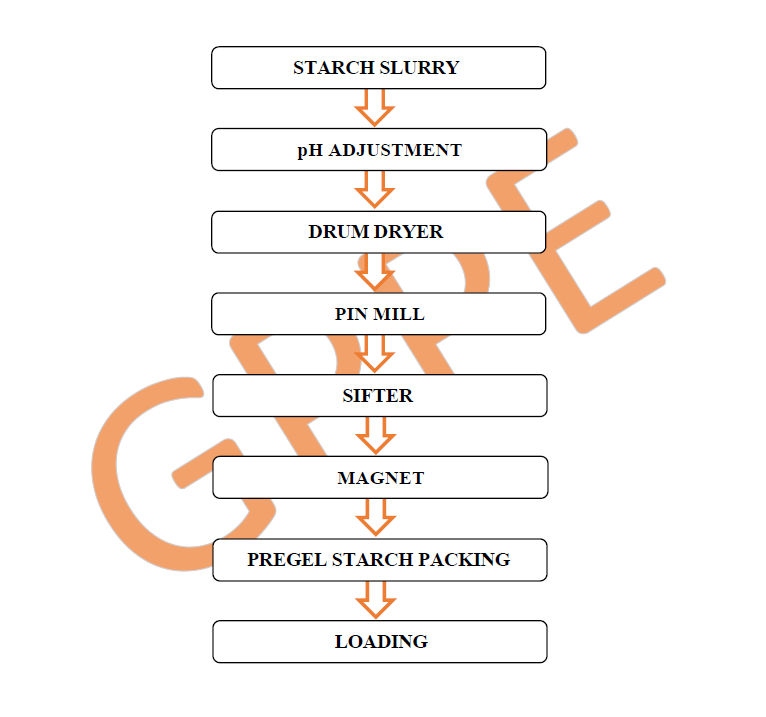

Pregelatinized starches can be produced by spray drying of precooked slurry, spray cooking, extrusion, the granular process, drum drying and other minor processes.

Each process has some advantages and disadvantages. However, drum drying process gives an acceptable final products at the lowest cost while comparing the other methods.

Drum drying is a continuous indirect drying method. Product is dried by spreading and forming thin and uniform layer on the heated surface of the drum. Due to the kneading effect of the applicator rolls and the capability of scraping the product from drum surface easily, the dryer is unique for the drying of viscous, pasty and sticky materials. Because of the short retention time, no heat damage will ocur during drying process at high temperatures.

In drum drying process, there is no direct contact between steam and product. The drum drier surface is heated by steam from inside. The product is going to be gelatinised is feed to the surface of the drum beetween applicator rolls. Applicator rolls paste gelatinized product to the surface of the drum as a thin layer while the drum is rotating. When the thin layer is in contact with the heated surface, the liquid inside the gelatinized product evaporates very quickly. Thin layer of gelatinized and dried product is scraped off at every complete rotation of the drum in the form of a film or a powder.

The main reasons for pregelatinized starches used in different industrial sectors is that they demonstrate rapid viscosity development in water without cooking and also they bind and retain moisture at high levels.

EN

EN

TR

TR